Only an hour west of Helsinki, the Feenix rises from an old sanatorium. The Hub is a place to create, learn and regenerate.

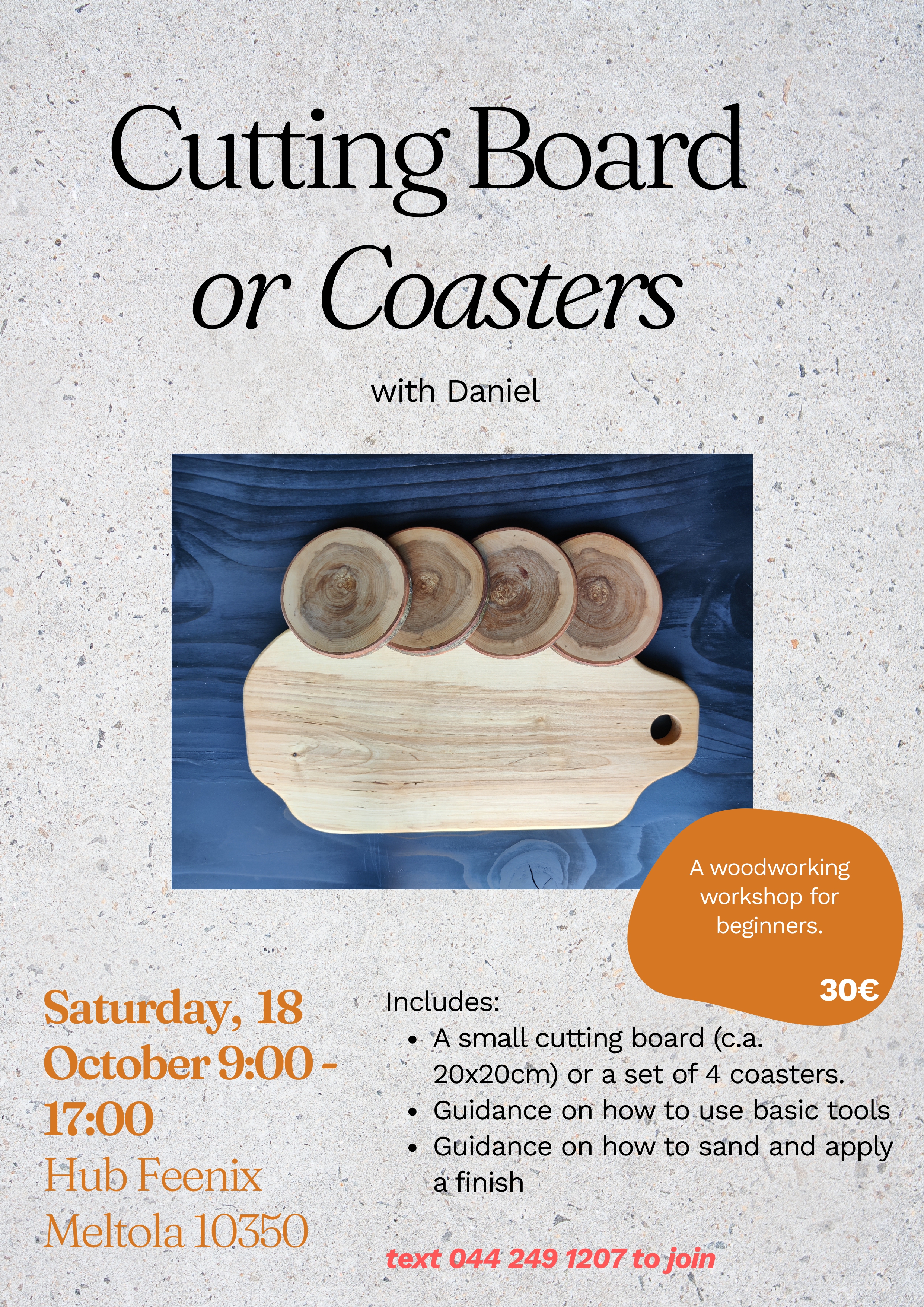

In this workshop, you will create a cutting board or coaster from start to finish. Learn how to use b . . .

In this Workshop we will design a 3d model in TinkerCAD with focus on 3D printing. You will learn how . . .

Hub Feenix on viisi vuotta sitten perustettu yhteisö ja kansainvälisen ekoyhteisöjen verkoston GEN Eu . . .

Retriitit ovat hyvin transformatiivisia kokemuksia, joissa voit kohdata itsesi, pysähtyä ja linjata e . . .

Hub Feenix, a beacon of creativity and community, is located in the beautiful Finnish countryside, only one hour from Helsinki. We have different sized studios and spaces to accommodate retreats for up to 100 people.

We offer a wide range of studios to suit any type of artist. We have large and small rooms available, with differing levels of natural light, as well as rooms for wet work, small dance studios, and more.

The Hub encourages everyone to be creative in any way they choose. We provide facilities for traditional crafts, like sewing and woodwork, and modern technologies like 3D printing and electronics.

We have various coworking and office spaces to rent. You can join us in our coworking area for the odd afternoon or rent your own office - or even wing - long-term. Spaces of 15 – 500m2 are available.

We offer short to medium term accommodation for several target groups. The rooms are generally of a corridor, either with or without own toilet and shower.

Hub Feenix has an international artist residency program. Visual artists, musicians, writers, craftmakers etc can apply for a residency for 1-3 months. In 2023 we had 19 artists, in 2024 there are 37 artists from all around the world staying with us. We can accommmodate about 4-10 artists at the time. The artists live in their own wing, with shared kitchens and other facilities.

Our café serves vegan and vegetarian food, tea, coffee, and delicious treats. It's an atmospheric and cozy place for sitting down and relaxing, by yourself or meeting with others.

Open when events are happening.

In our Healing salon you can get professional help for osteopathy, shiatsu, acupuncture and more. You can also take care of your hair in a natural way at our Eco Hairdressing salon, with high quality organic haircare products.

Open on request.

In our Boutique, you can find organic and natural cosmetics, buy our great Hub Feenix tea mixes, and browse inspirational art from our artists.

Open when events are happening.